Cost-efficient tug fleet service and maintenance

The tugboat fleet or whatever vessel fleet has a need of service and maintenance. What are the most important issues to succeed with that and what is needed to be taken in concern when planning your fleet service and maintenance (S&M) activities. How you can measure it and get your operational performance wanted level. There are many things that influence to the result, national and international authorities and regulations, operating area and conditions, fleet combination, assisted type of vessels, crew and management capability, and how the all S&M activities are arranged.

Tugboat cost structure

The investigations showed what are the main costs of tugboat fleet. It consists of below listed 6 elements. Clearly highest part of all costs are the wages of the crew. But next comes the service, maintenance, docking, and repair (S&M). All S&M costs has an influence on all others in the list. Mainly well serviced and maintained vessels consumes less fuel and lubrication oil, crew can concentrate their main tasks, classification process is easier and cheaper, businesswise the ordered works get done and the company will get the thrust and respect in the market. And most of all from the company perspective it should more profitable.

- Fuel

- Lubrication oil

- Wages of the crew

- Classification

- Service, maintenance, docking, and repair

- Management and financing

Even though S&M is a support function, it must be planned from the beginning to be part of the business culture. There is no other way to succeed on that. Other issue is how to manage it and how to measure it. The maintenance performance measurement (MPM) system (Parida & Kumar 2006) is stating “what cannot be measured cannot be managed effectively”. The company needs to know the status of its fleet more less on-line that they can act correct way when needed to keep the business running. Main purpose of the S&M is to keep “asset” the boats safe, operational, and available when needed.

What you need to take in consideration in fleet S&M

The fleet vessels need to be drydocked according to the authorities and classification rules. Normally it means dry-docking every 5th year and an intermediate inspection once during the year 3 in given time window. International Maritime Organisation (IMO) assembly of International Safety Management Code (IMSC) (IMO 2018) is giving guidelines where there are three main goals: the safety of people on board, the safety of the ship and cargo, and the safety of environment. These requirements give the base for all S&M activities onboard the vessel and to the management.

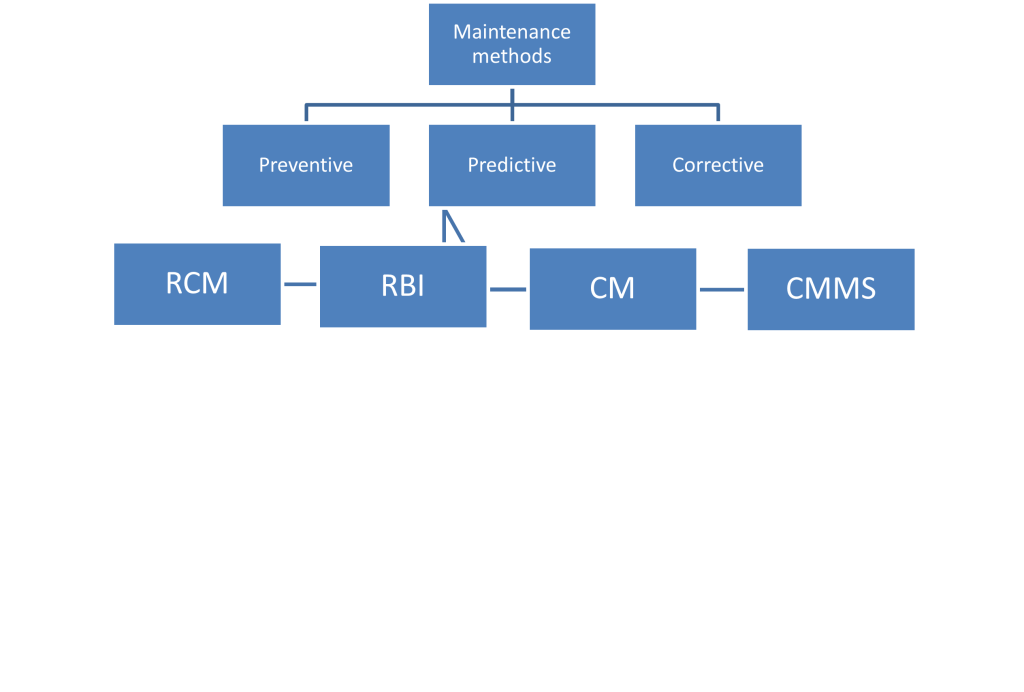

When going through the articles related to this topic of service and maintenance, it was found out that the methods can be divided to basic elements which are shown in figure below, Maintenance methods, (Lasakis et al. 2009) . It shows in quite a simple way what are the basic modern methods for executing the service and maintenance. These include:

- Reliability Centred Maintenance (RCM)

- Risk Based Inspection (RBI)

- Condition Monitoring (CM)

- Computerised Maintenance Management System (CMMS).

These are the functions that must be taken in consideration in all aspect from the beginning when planning a newbuilding or making conversion to existing vessel. All service and maintenance activities are easier, cheaper, and more effective to do in advance in the harbour rather than offshore. To be predictive in your actions you must create a system to follow up and to help on decision making to save the costs of your assets.

To get realistic data and feedback from whatever system or strategy you choose the major issues is the engagement of the employees. They need to be trained to use the systems, know the targets, and the idea what the company is going to achieve. There was seen cultural difference between the crews. So, if you want to succeed you have to take all employees with to run the process through and continue the training and demand further as a part of the continues improvement of you working environment and company culture.

New technologies on maintenance planning and follow up will help and give more information that can make the company to avoid unnecessary docking and other ways to make the company do the docking early enough to avoid more expensive damages or safety risks. Risks can be also shared with service agreements with shipyards or equipment manufacturers. The recommended service activities will be done according to the plan. Safety level will be increased, and downtime decreased.

Alternatives to effectively manage your fleet S&M

When the company was doing minor repairs and service works, they were using own dedicated service team. That was very competitive compared to any subcontractor. Subcontractors did not always know the vessels and what are the conditions there and they do not have flexibility which is needed. Contractor cannot wait but the company’s own team can do other things instead and there are the big benefits behind it. The own team always knows what can be expected and what are the requirements.

Sources

Master thesis. Marine Technology, Kalle Hartikainen (2023). Service and maintenance development in a shipping company